Understanding Control Cable Standards A Comprehensive Guide

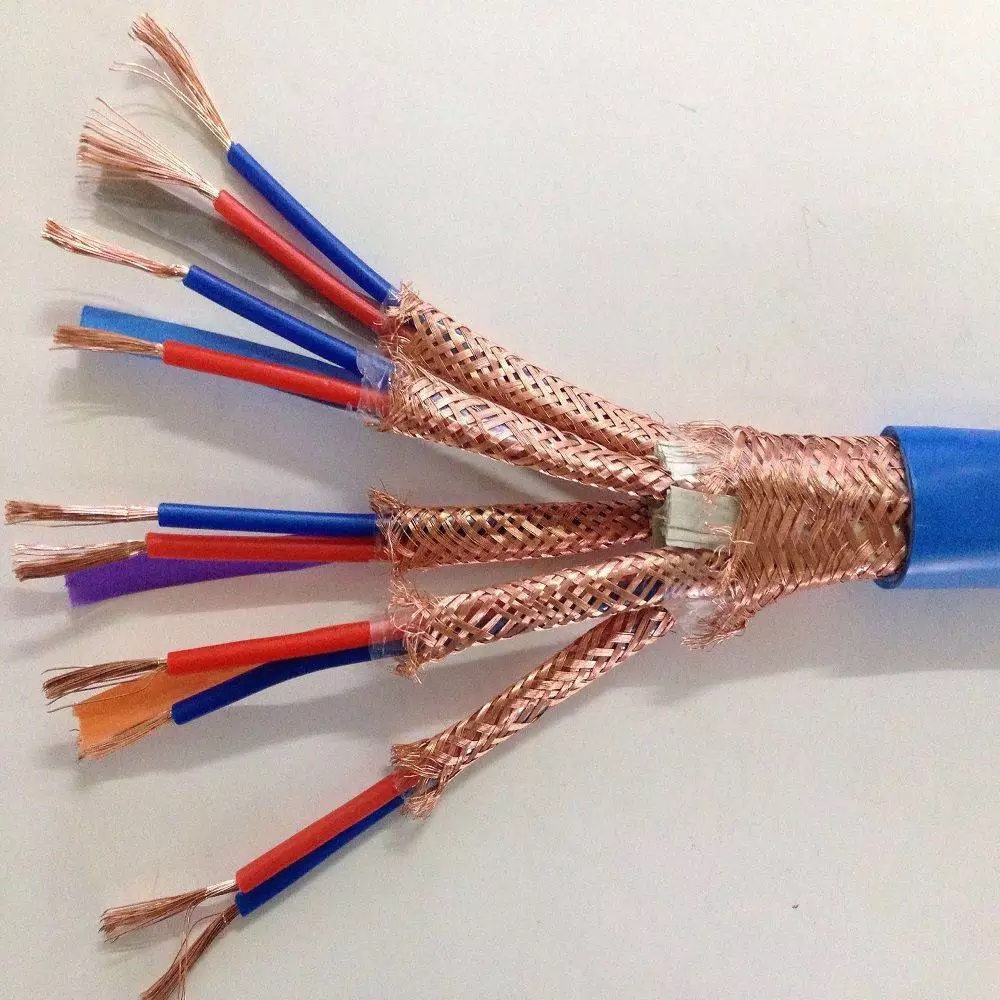

Introduction Control cables play a crucial role in various industries, providing a means to transmit signals for controlling and monitoring equipment. These cables are designed to ensure smooth and reliable operation of machinery and systems. To maintain consistency and quality across industries, control cable standards have been established to guide manufacturers in the production of these essential components. In this article, we will delve into the world of control cable standards, exploring their importance, key specifications, and common standards used in the industry. Importance of Control Cable Standards Control cable standards serve as a set of guidelines that define the performance requirements, materials, construction, and testing methods for control cables. Adhering to these standards ensures that control cables meet specific criteria for safety, reliability, and compatibility with different applications. By following established standards, manufacturers can produce control cables that are consistent in quality and performance, making it easier for engineers and users to select the right cables for their needs. Standards also play a crucial role in facilitating interoperability between different components and systems. When control cables meet standard specifications, they can be easily integrated into existing setups without compatibility issues. This is particularly important in industries where precise control and monitoring are essential, such as manufacturing, automation, and transportation. Key Specifications in Control Cable Standards Control cable standards cover a wide range of specifications that are essential for ensuring the quality and performance of these cables. Some of the key specifications that are commonly included in control cable standards are: 1. Conductor Material: The conductor material used in control cables can vary depending on the application. Common conductor materials include copper, aluminum, and tinned copper. The choice of conductor material can impact the cable's electrical conductivity, flexibility, and resistance to corrosion. 2. Insulation Material: Insulation material is crucial for protecting the conductor from external elements and preventing electrical leakage. Control cable standards specify the type of insulation material to be used, such as PVC, polyethylene, or rubber, based on factors like temperature range, chemical resistance, and mechanical durability. 3. Shielding: Shielding is important for controlling electromagnetic interference (EMI) and radio frequency interference (RFI) in control cables. Standards outline the requirements for shielding materials, such as foil, braided wire, or a combination of both, to ensure optimal signal transmission and noise immunity. 4. Voltage Rating: Control cables are designed to operate within specific voltage ranges, depending on the application. Control cable standards define the voltage rating that cables must meet to ensure safe and reliable operation in different environments. 5. Temperature Rating: Temperature rating specifies the operating temperature range of control cables. Different applications may require cables that can withstand extreme temperatures, so standards define the minimum and maximum temperature limits that cables should be able to endure. 6. Flexibility: Control cables often need to bend and flex during installation and operation. Standards may include requirements for the flexibility of cables, such as minimum bend radius and maximum flex cycles, to ensure that cables can withstand repeated bending without damage. Common Control Cable Standards Several organizations worldwide develop and maintain control cable standards to ensure consistency and quality in cable manufacturing. https://www.jiangyuancables.com/pvc-insulated-sheathed-power-cable/ of the most widely recognized control cable standards include:  1. National Electrical Manufacturers Association (NEMA): NEMA is a U.S.-based organization that develops standards for electrical equipment, including control cables. NEMA standards cover a wide range of electrical products and systems, providing guidelines for manufacturers and users to ensure safety and performance. 2. International Electrotechnical Commission (IEC): The IEC is an international standardization body that develops and publishes standards for electrical, electronic, and related technologies. IEC standards are widely adopted globally and cover various aspects of control cable design, testing, and performance. 3. Canadian Standards Association (CSA): CSA develops standards for a range of products and systems, including control cables. CSA standards are widely used in Canada and internationally, providing requirements for cable construction, materials, and performance. 4. European Committee for Electrotechnical Standardization (CENELEC): CENELEC develops standards for electrical and electronic products in Europe. CENELEC standards cover control cables and other components used in industrial and commercial applications, ensuring compliance with European regulations and requirements. 5. Underwriters Laboratories (UL): UL is a U.S.-based organization that tests and certifies electrical products for safety and performance. UL standards cover control cables and other electrical components, providing assurance that products meet the necessary requirements for use in various applications. Conclusion Control cable standards play a vital role in ensuring the quality, safety, and performance of control cables used in diverse industries. By adhering to established standards, manufacturers can produce cables that meet specific criteria for materials, construction, and testing, enabling reliable operation in different applications. Understanding the key specifications and common standards in control cable manufacturing is essential for engineers, designers, and users to select the right cables for their needs. As technology continues to advance, control cable standards will evolve to address new challenges and requirements, driving innovation and excellence in cable design and production.

1. National Electrical Manufacturers Association (NEMA): NEMA is a U.S.-based organization that develops standards for electrical equipment, including control cables. NEMA standards cover a wide range of electrical products and systems, providing guidelines for manufacturers and users to ensure safety and performance. 2. International Electrotechnical Commission (IEC): The IEC is an international standardization body that develops and publishes standards for electrical, electronic, and related technologies. IEC standards are widely adopted globally and cover various aspects of control cable design, testing, and performance. 3. Canadian Standards Association (CSA): CSA develops standards for a range of products and systems, including control cables. CSA standards are widely used in Canada and internationally, providing requirements for cable construction, materials, and performance. 4. European Committee for Electrotechnical Standardization (CENELEC): CENELEC develops standards for electrical and electronic products in Europe. CENELEC standards cover control cables and other components used in industrial and commercial applications, ensuring compliance with European regulations and requirements. 5. Underwriters Laboratories (UL): UL is a U.S.-based organization that tests and certifies electrical products for safety and performance. UL standards cover control cables and other electrical components, providing assurance that products meet the necessary requirements for use in various applications. Conclusion Control cable standards play a vital role in ensuring the quality, safety, and performance of control cables used in diverse industries. By adhering to established standards, manufacturers can produce cables that meet specific criteria for materials, construction, and testing, enabling reliable operation in different applications. Understanding the key specifications and common standards in control cable manufacturing is essential for engineers, designers, and users to select the right cables for their needs. As technology continues to advance, control cable standards will evolve to address new challenges and requirements, driving innovation and excellence in cable design and production.